Wras Valves

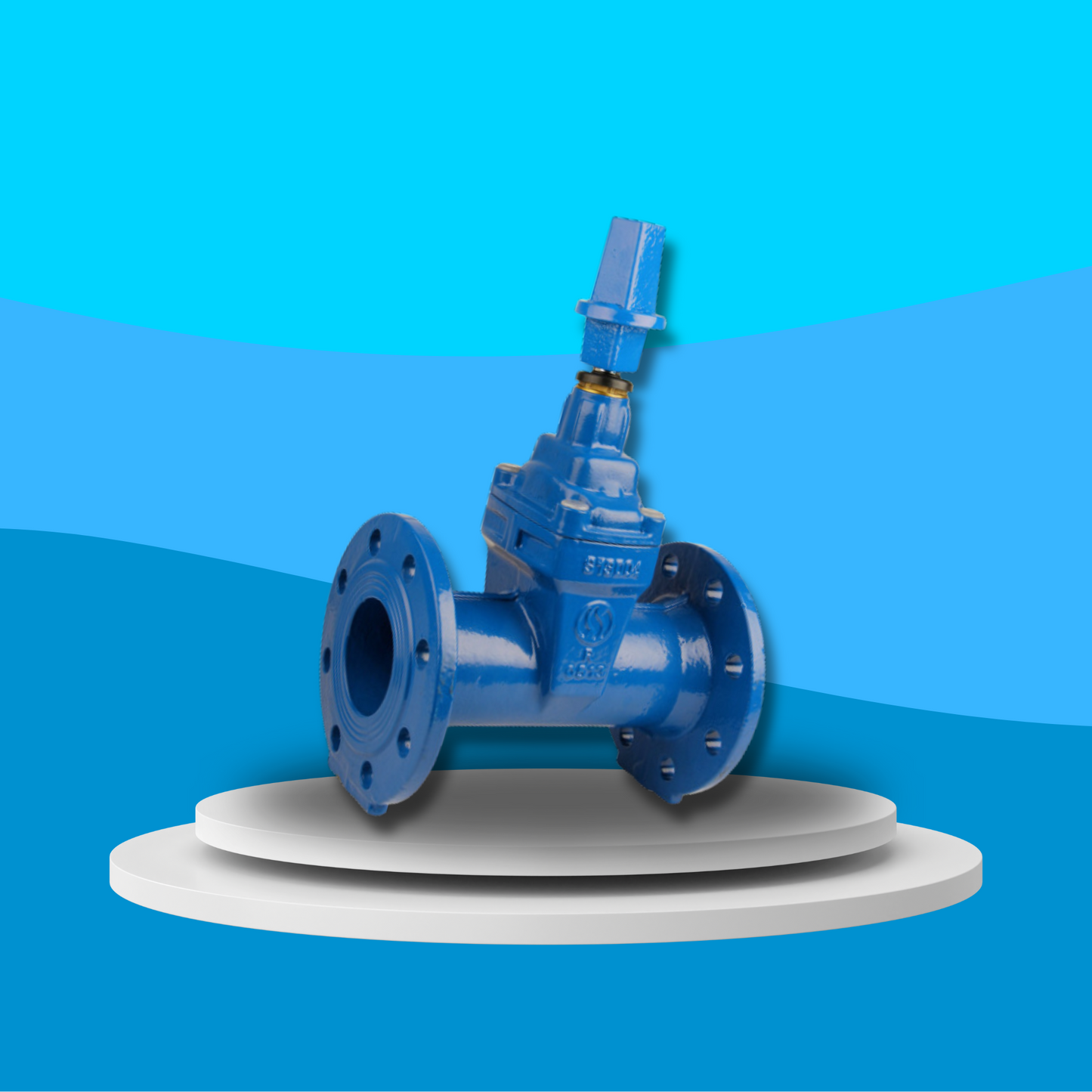

WRAS Approved Sferaco Gate Valve

WRAS Approved Sferaco Gate Valve

Couldn't load pickup availability

WRAS Certified

Introducing the WRAS Approved Sferaco Gate Valve, meticulously engineered for superior water distribution performance. This range includes EPDM and NBR Wedge models, each designed with a full bore, stainless steel non-rising stem, and ductile iron wedges coated for enhanced durability. The Sferaco Gate Valves feature protected screws, heel positioning, and the ability to change stem gaskets under pressure, ensuring optimal functionality and reliability in diverse applications.

Key Features:

- WRAS Approved: Certified to comply with stringent WRAS standards for water safety and quality.

- High-Quality Materials: Full bore, stainless steel non-rising stem, and ductile iron wedges coated in EPDM or NBR.

- Enhanced Durability: Coated with EPDM or NBR for superior durability and resistance.

- Versatile Operation: Supports a wide temperature range from -10°C to +70°C and pressures up to 16 bars.

- Leak-Proof Design: Features like protected screws and the ability to change stem gaskets under pressure ensure a secure, leak-proof performance.

- Easy Integration: Designed for seamless integration into existing water distribution systems.

Specifications:

- Material: Ductile Iron Wedge with EPDM/NBR Coating

- Approval: WRAS Approved

- Bore: Full and Total

- Stem: Stainless Steel Non-Rising Stem

- Closing Direction: Anticlockwise to Close (EPDM Wedge), Clockwise to Close (NBR Wedge)

- Sliding Pad: Up to DN200

- Retention Area: None

- Bonnet Gasket: NBR

- Stem Protection: 3 NBR O-Rings, Dust-Coat

- Pressure Maintenance: Change Stem Gasket Under Pressure (DN80 to DN600 for EPDM, DN80 to DN300 for NBR)

- Painting and Coating: Epoxy, RAL 5005, 250 µm

- Flanges: PN10/16 Flanges R.F.

- Usage: Water Distribution

- Temperature Range (Ts): -10°C to +70°C

- Max Pressure (Ps): 16 Bars (PN16 up to DN400), 10 Bars (PN10 from DN200 to 600)

FAQs

What is a WRAS-approved valve?

A WRAS-approved valve is a valve that has been certified by the Water Regulations Advisory Scheme in the UK. This certification ensures that the valve complies with the strict standards for materials and construction, making it safe for use with potable water systems.

Why is WRAS approval important for valves?

WRAS approval is important because it signifies that the valve will not cause water contamination or pose a health risk when used. This is crucial for maintaining the safety and quality of drinking water.

How can I identify a WRAS-approved valve?

WRAS-approved valves are typically marked with the WRAS logo and a unique approval number. These identifiers can usually be found on the body or packaging of the valve.

What types of valves can be WRAS approved?

Any valve intended for use with potable water can be WRAS approved. Common types include ball valves, check valves, gate valves, and pressure reducing valves.

Where are WRAS-approved valves typically used?

WRAS-approved valves are used in residential, commercial, and industrial water systems where there is direct contact with drinking water. They are essential in systems requiring high standards of hygiene and safety.

Are WRAS-approved valves required by law?

In the UK, water fittings that come into contact with the public water supply must comply with the Water Supply (Water Fittings) Regulations or Scottish Byelaws. These require that components such as valves do not contaminate water and are of an appropriate quality, often necessitating WRAS approval.

What are the benefits of installing WRAS-approved valves?

Installing WRAS-approved valves helps ensure compliance with water safety regulations, prevents water contamination, and enhances the reliability and longevity of water supply systems.

How do I install a WRAS-approved valve?

Installation of a WRAS-approved valve should follow manufacturer guidelines and local plumbing codes. It's recommended to hire a qualified plumber to ensure proper installation and operation.